Blog (61)

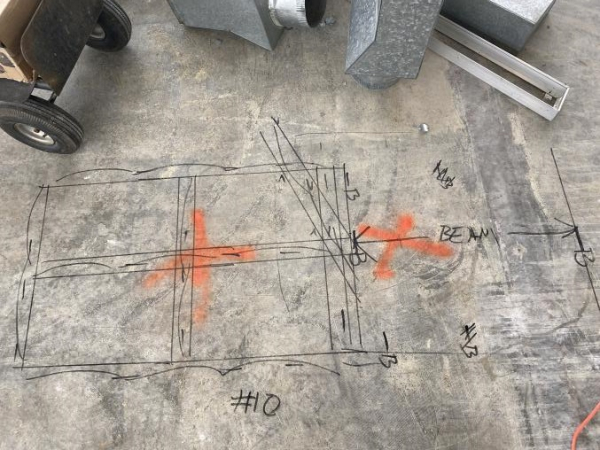

Using GPR to scan saw cuts or cores for renovation work can be a massive time and cost saver. Hitting even just one conduit or PT cable and set back a project's timeline by a few days this will also be a costly repair. One average our GPR techs find an object of importance directly under the zone to be cored in 1 of every 5 scans. In slab on grade saw cuts, this is much higher. One hit conduit cost around 35 to 40 scans to repair with PT cable costing even more. Always scan before you core or cut into concrete it will save you money and time over the life of the renovation.

GPR ConcretGPR Concrete Scanning can locate the edges of beams by tracking the thickness of the slab. GPR Concrete Scanning can also find beams by the steel pattern, depth, and quantity of steel located inside. It saves time and money to know your beam locations and saw cut, or core around them.

GPR Concrete Scanning for Beam Locating can remove the risk of coring into structural steel. GPR can locate beams in raised slabs as well as footers in slab-on-grade applications. Damaging critical structural can be an expansive fix, one that is completely avoidable.

Before cutting, coring, or drilling any concrete, certain steps should be taken. The two common and effective non-destructive methods are concrete x ray and Ground Penetrating Rader (GPR). There are advantages and disadvantages attached to both, and it is important to understand their differences and benefits to make the right choice.

GPR waves are equal to those of a cell phone or wifi network while X-rays needs a 50 feet clearance before usage for safety reasons. Generally, GPR is the cost-effective option and the faster method of concrete testing. The clarity of GPR is high but does not give the same resolution in concrete as x-ray. Concrete slab x rays target elevated slabs or the renovation of concrete wall surfaces where both sides of the structure are accessible. In GPR you only need one side of the surface accessible.

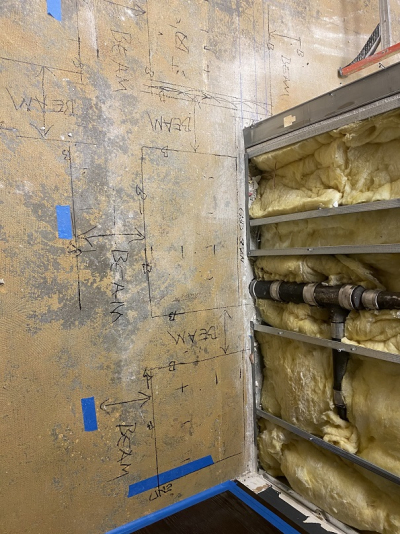

With GPR we can evaluate the contents of concrete walls. We can locate and find any structural steel as well as locate anything else that might of been casted in the wall however rare of an occasion this might be. Another useful thing is we can tell the thickness of the wall being cored. If your planning 20 cores in a wall your expecting is 5 inches and it turns out to be 12 inches+ your planed times schedule might not work out, and your coring guys are going to be very unhappy. Even if you are just wanting to save some time scanning can be very useful for a project. For coring through concrete on average each time you hit rebar it can take as long to core through that as the rest of the concrete you are passing through. If you need 40 cores done quickly, placing them in ways to avoid all steel could have time savings up to 400%.

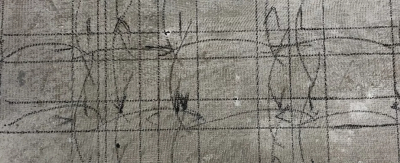

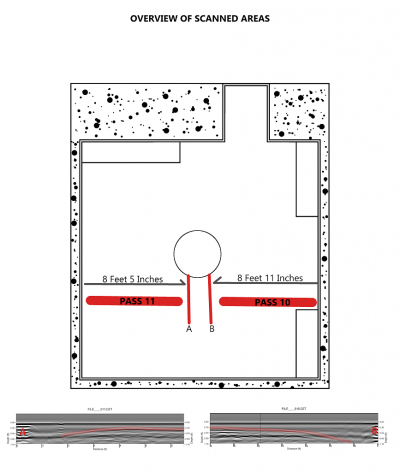

GPR can see a lot more than just metal objects. GPR sees the contrast of materials. In this example, you can see several distinct contrast objects. The top layer is the air above the concrete the first hard line is the top of a slab-on-grade. The distortion near the red line is wire mesh and the red line represents the bottom on the slab and the top of the grade. In this case, you can very clearly see the slab thicken. Objects A and B are metal ducts embedded under the surface of the slab. Reading GPR scan graphs come over time. To well seasoned GPR techs looking at scan graphs might as well be high-resolution pictures of the subsurface they are looking into.

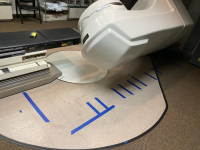

Ground Penetrating Radar is non-invasive, and because of this, it can be done during operational hours. In 24 hour medical facilities this is critical. Before any renovation work is done at any major hospital they always require GPR scans to locate any and all objects in the slab. Coring or drill into a conduit in these applications could have fatal consequences. As such many medical facilities exclusively use Xenogenesis for there GPR needs. We maintain the same level of precision across all our scans, whether we are scanning an Intensive Care unit or a hotel lobby, we maintain over 99.9% accuracy, and even guarantee all elevated slab scans. This is the only GPR guarantee in the industry because we stand behind our work.

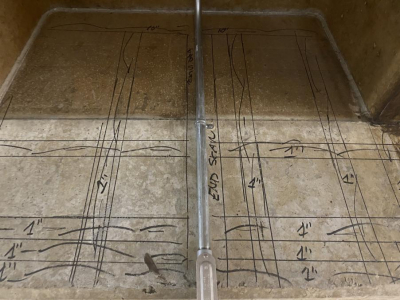

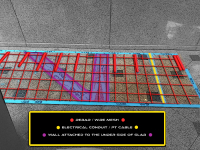

Our client needed to core 2 locations in this area. We did some GPR scanning and found clear locations that were clear of steel or other obstructions. One of the locations that were originally planned would have been right on top of a conduit. This is another example of saving money but getting scanning.

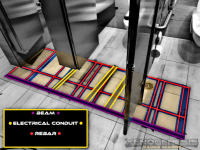

In this scan location, we found a high concentration of electrical conduits. The original location of the core was going to pass through two electrical conduits embedded in the slab. This was simple to avoid by moving the location 3 inches to an area clear of any steel or conduits. Call before you dig, and scan before you core.

Ceramics do not inherently affect Ground Penetrating RADAR in a different way than other hard building materials like concrete. What can happen in some cases is that a wire mesh will be placed under the tiles in the grout layer and this creates a faraday cage that will block the signal from above. This effects both GPR and X-ray. However, if the slab is elevated then it can be scanned from the underside. This will show the technician the contents of the slab up to the wire mesh mat layer that is under the tiles. The only case that would not able to be scanned is tile that has the wire mesh layer in the grout and is slab-on-grade or elevated slab with metal pan.

More...

In many cases, a hole needs to be cored through a metal wall track to run electrical conduit for wall boxes. When this happends we will remove the wall track on the floor in the sections the scans are located and scan both sides of the wall. The job from the picture above, we found that the beam stopped just at the edge of the wall, and no steel was running parallel inside the wall. We did locate a run of electrical conduits that ran right through the third section of the wall. This was also the main location that was set to be cored with 4 cores. They just relocated the cores to the second and fourth sections and were able to avoid the electrical conduits all together. This was billed as 3 scans and came out to be about 1/15 of the price of hitting the conduits. In the long run, it is always cheaper to scan.

This is an office building in Charlotte, North Carolina. We were called because they thought there might be posttension cables / pretension cable in the slab on grade as is the case with many buildings located in Charlotte North Carolina. This is a cross-section from the electrical room that was slab on grade although we found no Post tension cables or Pre tension cables. We were able to prevent them from hitting two electrical conduits. Using GPR is a great way to locate and avoid issues before they become an expensive problem to fix.

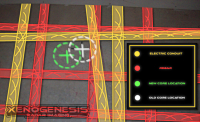

On this job we located one of the building's main electrical runs going right though zone that was set to be saw cut. This would of cost alot of time and money to repair. Situations like what could of happened can be easily avoided with GPR concrete scanning. #ground_penetrating_radar #concrete_scanning #electrical_conduit #elevated_slab #slab_on_grade

GPR scanning uses the contrasting properties of materials to view layers or objects located inside of those layers. When waves transition from one material to another and a portion of the waves reflect. The amount that reflects is based on the change in dielectric constant. An example of this is an air-filled pvc pipe vs a water-filled pvc pipe. The concrete has a dielectric constant of around 9 - 12 and air being 1 would give a contrast of around 10 and water being 81 would give a contrast of around 71. Both would be visible to the GPR technician however the water-filled pipe would show 7 times brighter on the GPR screen. Metal like that in electrical conduits, PT cable, and rebar have a contrast of 100, this means 100% of the signal is reflected back to the GPR receiver creating very dark pecks. This makes locating objects in a concrete slab a perfect case for GPR.

Ground Penetrating Radar - Archaeology - GPR - GPR Concrete Scanning - Geophysical Survey - Structural Analysis - GPR Concrete Scanning