Blog (61)

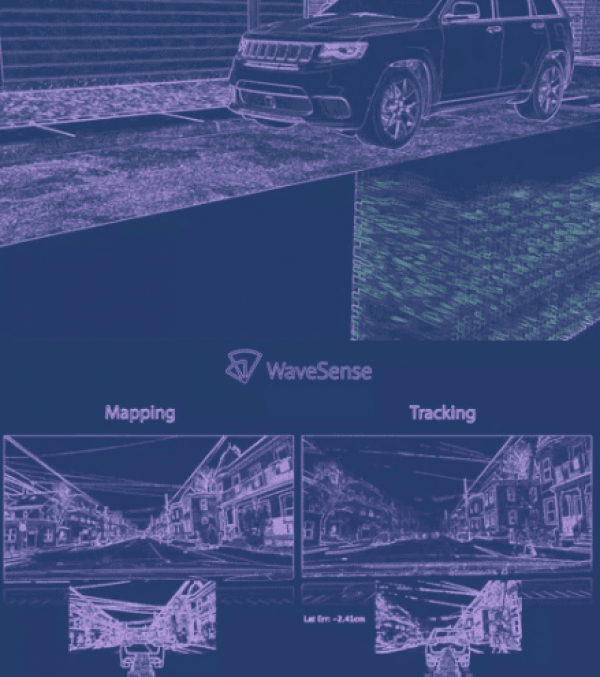

A company called WaveSense is trying to add Ground Penetrating RADAR into the array of sensors that are used on self-driving cars. WaveSense uses gpr + gps to map the road. This, in theory, could allow the vehicle to determine the location and position within a centimeter of accuracy.

WaveSense explains the need for the tech in this way

"Existing autonomous vehicle and ADAS technologies seek to recreate the perfect human driver by emulating human vision and cognition. But autonomous and driver-assisted vehicles can and must become safer than human drivers. Instead of imitating visual human driving, WaveSense’s ground-penetrating radar helps autonomous and driver-assisted vehicles see what humans cannot: that which lies below the ground.

WaveSense’s subterranean radar images enable a whole new dimension of sight. With the addition of subsurface data to above-ground camera and LIDAR sensor information, self-driving and ADAS-enabled cars now have a complete toolkit to work with when making driving decisions.

Safety is everyone’s #1 priority in the industry. Fusing several independent approaches—from cameras or LIDAR and GPS/INS to GPR—is the best way to ensure robustness, so that no one technology can cause a significant (and deadly) error. " -- the WaveSense Team

How effective this system would be in very wet or rainy conditions is still yet to be sceen. Another possible use case would be equipping the system to a sampling of government vehicles like that of the highway patrol. This would give valuable real-time data to the DOT on the conditions of our highway infrastructure, and bridges. As well as information on areas of black ice or other potential hazards such as developing sink holes, before they become a problem.

For more Information on WaveSense you can find them at https://wavesense.io/

And for more information on GPR you can visit us at xenogenesis.net

Ground Penetrating RADAR discovered a viking ship at Romsdal County in Norway. The ship dates back to the Viking period or Merovingian period. The length of the ship was between 50 to 55 feet, and more than 1000 years old. Traces of a settlement was also found along with burial mounds. The discoveries were made by archaeologists from the Norwegian LBI ArchPro. This is not the only ship they have located through GPR. To learn more about LBI and the discoveries they are making you can find them located here: https://archpro.lbg.ac.at/

Why is using GPR Concrete Scanning to find steel depth important in external applications important?

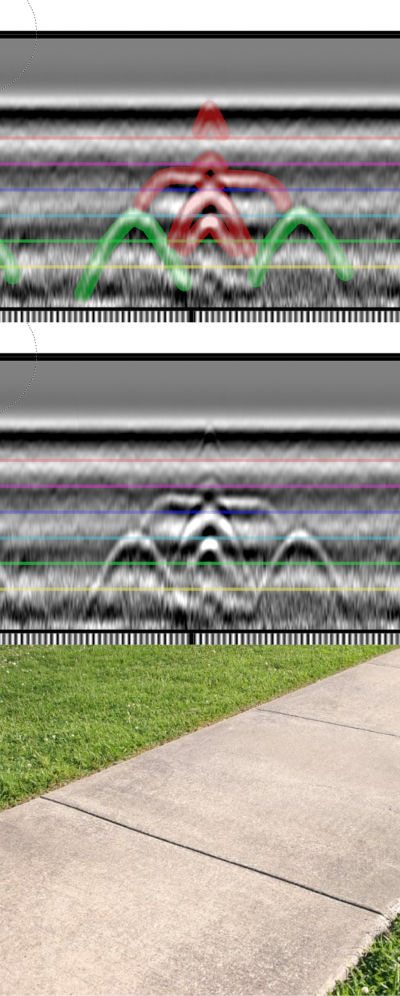

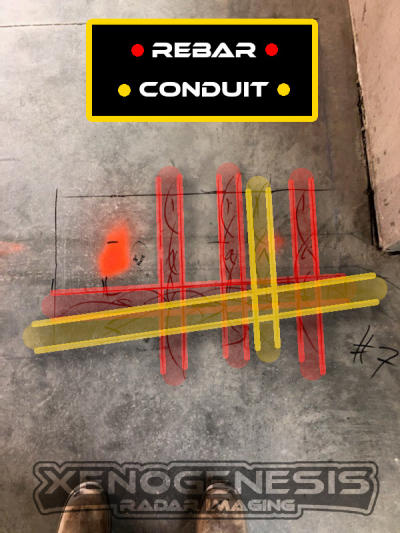

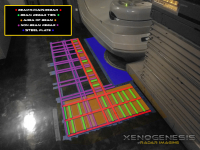

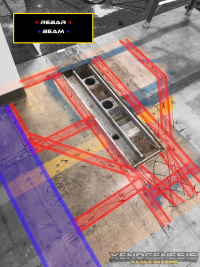

In GPR Concrete Scanning context and experience is very important. Knowing what peaks are the steel you are looking for and what peaks to ignore. GPR reads the contrast of materials ie (the difference in relative dielectric constant) It is not just looking for metal objects. The reason GPR is used to locate metal in so many applications is that metal is 100 on the dielectric scale where most concrete falls between 4 to 12 with even very green concrete no going to much past that point. This means the contrast is always going to be massive. Air is 1 on the dielectric scale and water is an 80 this is important because there is about the same change in the dielectric constant going from concrete to metal as there is in air to water. In the picture above there are two rebar ties(green) and an expansion joint(red). This data was collected on a rainy day and the join had collected some runoff. This made each joint we passed leave a strong hyperbola. There are lots of other causes for "false peaks" but with experience they become easy to spot.

In this GPR Concrete Scanning job, we were able to locate the grade beams by the depth of the rebar and the presents of rebar ties or saddles. We were also about to locate the large metal plate reinforcing the floor for the heave medical machinery. GPR Concrete Scanning only needs access to one side of the slab, so unlike x-ray, it can make easy work of slab on grade applications.

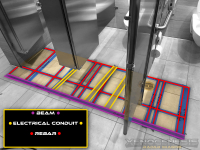

On this GPR concrete scanning job, we found an unusual pattern in this elevated slab. They used metal pan and left a trench unfilled with concrete. This trench had a metal plate above and below it to create a walkerduct like system. We do not encounter this style of construction too often on GPR concrete scanning jobs.

They needed to core 2 new holes in this area so we did some scanning and found them several places that were free of steel. One of the locations that were originally planned would have been right on top of a conduit this is another example of saving money but getting scanning.

More...

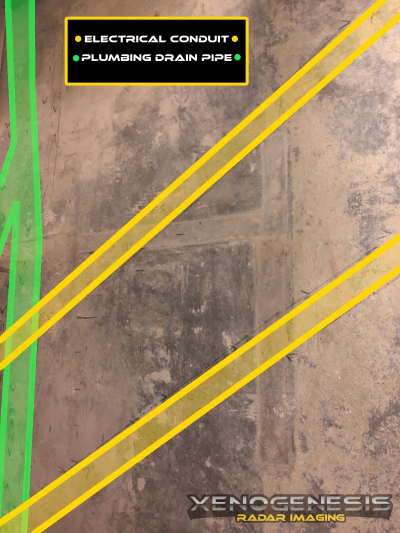

This conduit was in the path of a saw cut need to link up with the drain. Our GPR was able to locate it so the saw cutting company was able to chip around the conduit and avoid the issues that cutting this 240 volt line would have caused. GPR for Slab-on-Grade applications works very well for anything ran inside the slab. However, depending on the number of voids in the gravel layer locating runs in the dirt is not always possible. In this case, the conduit in the concrete was easy to locate, but the drain pipe under the slab ran in the dirt was not visible to GPR.

This warehouse needed to add more bay doors for drop-offs. Unfortunately, both locations contained large structural support columns. In this case, we were able to help them position the door locations between the supports in a manner the building engineer felt conferable with.

Ground Penetrating Radar - Archaeology - GPR - GPR Concrete Scanning - Geophysical Survey - Structural Analysis - GPR Concrete Scanning